Here you go friends a "how I did it" post , some of you may want to try this and some of you might just let your LBS handle a mod like this.

Some of this stuff will probably work on other bikes besides a Schwinn !

So for those of you who have the skills for this... follow along , I wont say this is the final word it is just how I made it work and some of these steps may not apply to your bike but some will.

The parts...to do this conversion you will need to have a disc brake equipped wheel, a caliper mount and caliper, a brake lever and cable, the disc rotor and mounting bolts ...you may also need some bushings..I did.

First step after aquiring the parts...setting up the wheel...you can do this a couple ways , you could buy a wheel thats disc ready or you could get a bmx style flip flop hub and a spin on rotor adaptor and lace it to your rim of choice...I chose a ready made wheel and bolted on the rotor

next..fit the wheel to the bike..the wheel I chose was a single speed freewheel set up but I wanted multi speed so since I had a 5sd cog thats what I put on it and that requires some adjustment to the cones to get everthing spaced properly and the rim centered in the frame...I might add that the rim also had to be reset on the hub...done by loosening the spokes on one side and tightening on the other ...equally !

Check your clearances closely

The caliper mount..again a couple ways to go about this but for this conversion I went with the US Choppers billet mount...like my old hot rod days these aftermarket parts dont fit they have to be made to fit .

I wanted the caliper down and back behind the drop out so the mount had to be on the inside of the dropout...a little cold stretch on the stays to get it all to fit.

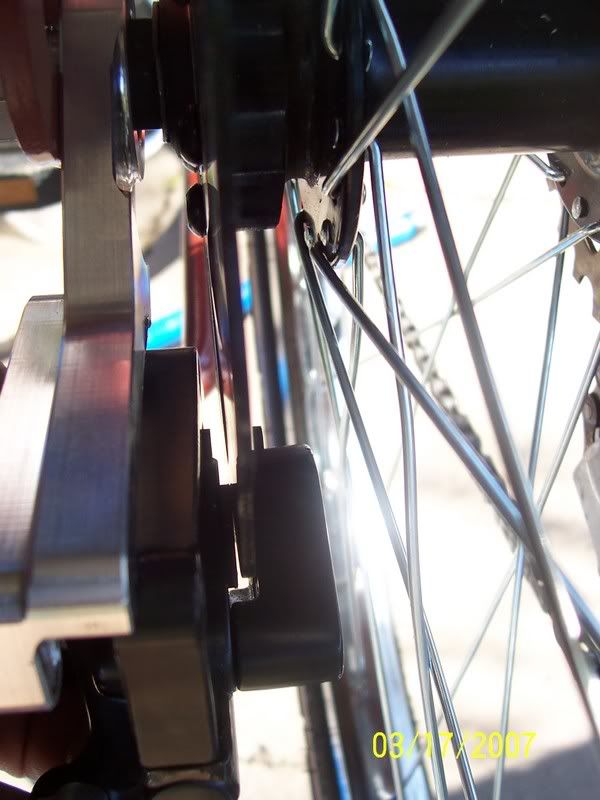

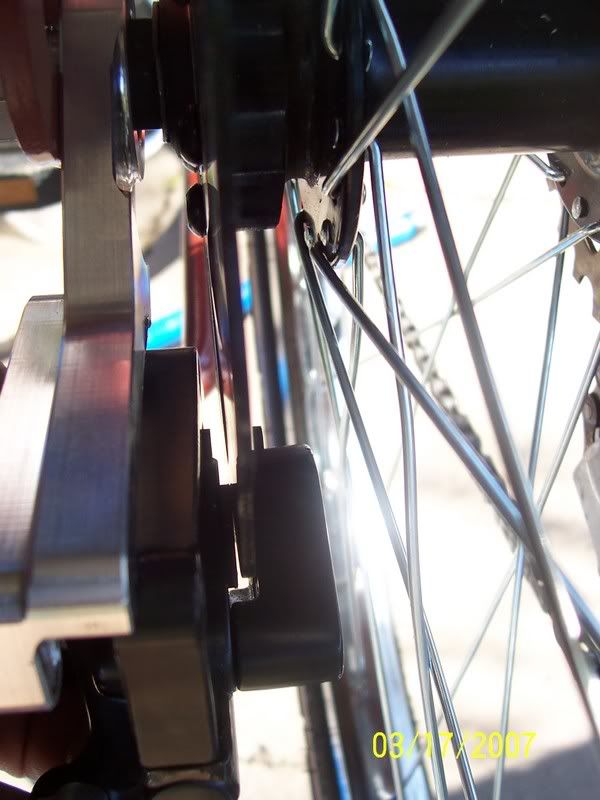

now fitting the cailper...with disc brakes its very important to get as much pad contact with the rotor as possible and the caliper must be centered over the rotor ...a few steps here. start by setting up the lever and cable and connect it to the caliper

now you have to use your eys and your brain some here ....hold the caliper over the rotor , have an assisant squeese the lever..the caliper should hold on the rotor if not adjust the cable a bit tighter now measure the space between the mount and caliper...that measurment is the thickness of the bushing you will need...mine was right at 1/4 in. and I found some at the hardware store in chrome even. 2 required I also got a couple 1/16 in thick for the out side of the mount ..you'll see why later.

this is also the time to measure what length bolt is needed for the mount to caliper.

now its time to get the most pad contact..with the caliper in place and bolted down, look at where the pad contacts the rotor and how much clerance between the caliper and rotor I needed to go up and in with the caliper about 1/4 in. Time to modify that billet bracket ...take the wheel back off again...jeez . to modify the bracket, first I drilled the mounting holes up and in slightly

then cleaned up the slots a bit

now it time to make some room for those bushing, I used a couple different carbide bits and a drum bit for this.

while doing the mods to the bracket take care not to remove to much material and keep everything paralell..the bushings must sit flat on the bracket, put the wheel and bracket back on and bolt it all together and recheck the fit. if all is ok you can now adjust the the cable and pad clearance . the inside pad is adjustable and can be done through the wheel.

now it s time to make a support bracket or you might end up with this

measure center to center between the outer caliper mount hole and the fender mount hole and tranfer that measurment to a peice of bar stock or other suitable material, drill the holes , cut the stock and round the corners, bolt it on and your done...take it out for a safe test ride !!

I hope some of you find this usefull

Mark

Some of this stuff will probably work on other bikes besides a Schwinn !

So for those of you who have the skills for this... follow along , I wont say this is the final word it is just how I made it work and some of these steps may not apply to your bike but some will.

The parts...to do this conversion you will need to have a disc brake equipped wheel, a caliper mount and caliper, a brake lever and cable, the disc rotor and mounting bolts ...you may also need some bushings..I did.

First step after aquiring the parts...setting up the wheel...you can do this a couple ways , you could buy a wheel thats disc ready or you could get a bmx style flip flop hub and a spin on rotor adaptor and lace it to your rim of choice...I chose a ready made wheel and bolted on the rotor

next..fit the wheel to the bike..the wheel I chose was a single speed freewheel set up but I wanted multi speed so since I had a 5sd cog thats what I put on it and that requires some adjustment to the cones to get everthing spaced properly and the rim centered in the frame...I might add that the rim also had to be reset on the hub...done by loosening the spokes on one side and tightening on the other ...equally !

Check your clearances closely

The caliper mount..again a couple ways to go about this but for this conversion I went with the US Choppers billet mount...like my old hot rod days these aftermarket parts dont fit they have to be made to fit .

I wanted the caliper down and back behind the drop out so the mount had to be on the inside of the dropout...a little cold stretch on the stays to get it all to fit.

now fitting the cailper...with disc brakes its very important to get as much pad contact with the rotor as possible and the caliper must be centered over the rotor ...a few steps here. start by setting up the lever and cable and connect it to the caliper

now you have to use your eys and your brain some here ....hold the caliper over the rotor , have an assisant squeese the lever..the caliper should hold on the rotor if not adjust the cable a bit tighter now measure the space between the mount and caliper...that measurment is the thickness of the bushing you will need...mine was right at 1/4 in. and I found some at the hardware store in chrome even. 2 required I also got a couple 1/16 in thick for the out side of the mount ..you'll see why later.

this is also the time to measure what length bolt is needed for the mount to caliper.

now its time to get the most pad contact..with the caliper in place and bolted down, look at where the pad contacts the rotor and how much clerance between the caliper and rotor I needed to go up and in with the caliper about 1/4 in. Time to modify that billet bracket ...take the wheel back off again...jeez . to modify the bracket, first I drilled the mounting holes up and in slightly

then cleaned up the slots a bit

now it time to make some room for those bushing, I used a couple different carbide bits and a drum bit for this.

while doing the mods to the bracket take care not to remove to much material and keep everything paralell..the bushings must sit flat on the bracket, put the wheel and bracket back on and bolt it all together and recheck the fit. if all is ok you can now adjust the the cable and pad clearance . the inside pad is adjustable and can be done through the wheel.

now it s time to make a support bracket or you might end up with this

measure center to center between the outer caliper mount hole and the fender mount hole and tranfer that measurment to a peice of bar stock or other suitable material, drill the holes , cut the stock and round the corners, bolt it on and your done...take it out for a safe test ride !!

I hope some of you find this usefull

Mark