Hey, I had one of those differential units on a vintage JC Penny's riding lawnmower. The mower had an 8 hp briggs so the differential can take any abuse a human could put into the pedals. The mower came with my house that I bought in 1987 and the mower was old and worn out then. But I was able to get parts for it in 1988 or so. Seems silly but I can remember picking up wheels and steering nuckles at a store that is mostly clothes and household stuff. I'm still guessing 1970s on your trike.

And you have a Shimano 3 speed intermediate hub. I didn't see that in the earlier photos. That can be made to work. New cable and shifter. Probably needs lube. Use a lightweight oil inside. No oiler port? Remove the shifter bell housing from the end of the axle, push rod and shoot some oil down the hollow axle. Helps to turn the bike on its side and spin the wheel at the same time. I have four trikes and three of them are single speed. Three gears really help with the riding so it's worth fixing the hub. Because the trike has that metal cover, the hub should be in good condition. FYI Shimano 3 speed hubs are incompatible with Sturmey Archer triggers and visa versa.

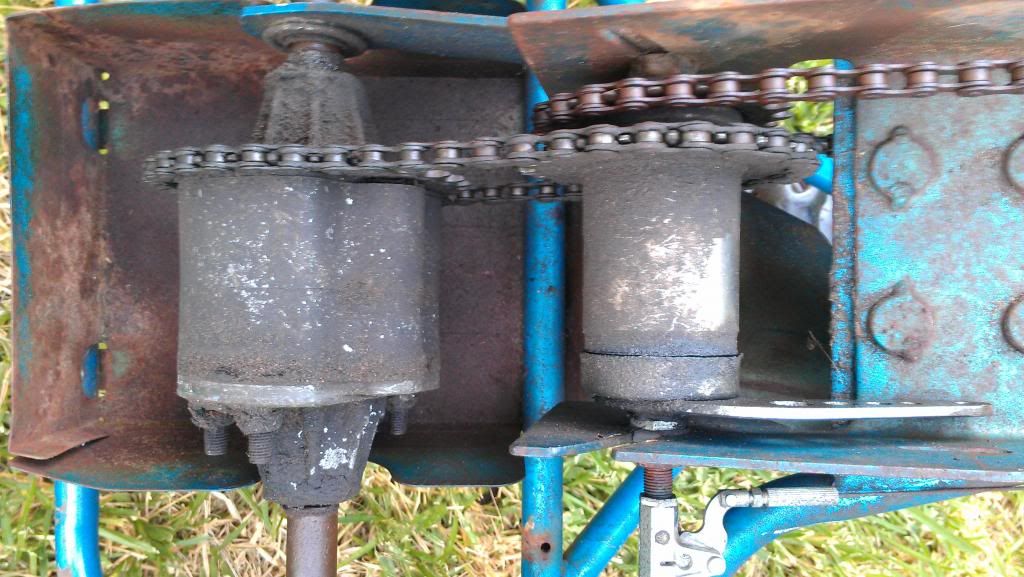

A degreaser will clean up the outsides of those units. They probably won't need tearing into.

The bent up hub flanges can be bent back in to shape when you remove the spokes. The metal is a mild steel and pretty easy to bend. A little wobble in the flanges won't affect the true of the wheel when you respoke them. Once you get the spokes off, you can clean the hub shells for painting. Or not, depending on your preference. They look to have been zinc plated or chrome plated otherwise they would be solid rust by now. The axle is not plated, thats why the hubs are stuck on. If you do ever get the hubs off, use emory paper to smooth out the axle rust and use lots of heavy bearing grease, like auto wheel bearing grease, where the hub slides on the axle to prevent future rusting up. Clean out the inside of the hub too. The grease will prevent water and dirt from getting in the space. Its the tight fit and dirt that hold water in there that causes the rust.

I can see the clevis pins just inside the inner flange. Those are to keep the wheels from turning on the axle. A rather unique way of doing that. IMO, a dumb idea to put such large holes in the axle right at the major stress point. I wonder if that was original. You can cut the pins off short and use a drift punch to drive them out. Or try to drill them out. Split clevis pins are easy to get at hardware stores.

As mentioned a ball Joint removal tool might work for pushing the hub off from the inside end. It will be pushing on the bearing unit on the frame. The tool could damage the bearing. Those bearings are quite easy to get and easy to replace once the hub & pin are out. Those bearings are commonly used in washing machines and wheel barrow wheels. Cheap.

What the tool looks like: