You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I dunno, she just flipped out! Fork? Yup!

- Thread starter jackdaw

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Re: I dunno, she just flipped out! More props.

Looking good man...I thing a regular spriger would look cool. 8) 8)

Looking good man...I thing a regular spriger would look cool. 8) 8)

Re: I dunno, she just flipped out! More props.

Those are some cool lines iven. I'm thinking about filling in behind the seat tube with some sheet of something. The downtube you drew is cool too but I'm going to leave it as is there so that it looks for sure like a flipped bike.

Thanks man!

I'm thinking about doing this with the seat, it would make it more rideable, I'd still be able to slam it but I could raise it too. It might look better?

viewtopic.php?f=21&t=43344&st=0&sk=t&sd=a&hilit=twisted+sister#p422921

Thanks for your input guys. You all know that it's hard sometimes to stay in it, you guys help.

iven said:i have a Suggestion.. :roll:

lemme know what you think :mrgreen:

Those are some cool lines iven. I'm thinking about filling in behind the seat tube with some sheet of something. The downtube you drew is cool too but I'm going to leave it as is there so that it looks for sure like a flipped bike.

FatBoy said:Lookin GOOD!!!! 8) :mrgreen:

Thanks man!

I'm thinking about doing this with the seat, it would make it more rideable, I'd still be able to slam it but I could raise it too. It might look better?

viewtopic.php?f=21&t=43344&st=0&sk=t&sd=a&hilit=twisted+sister#p422921

Thanks for your input guys. You all know that it's hard sometimes to stay in it, you guys help.

Re: I dunno, she just flipped out! More props.

OK, here's more.

A picture with a new seat compared to the old one. I think the small one looks too small. Having a functioning seatpost would make the bike a lot more comfortable. I'm not set on the fore and aft location but it will be over the seat tube rather than behind it. I think.

And the actual seat I would use, currently rusted to an old Raleigh :roll: It will clean up nice, it's a classy old Messinger.

And the way I would do the seat clamp, which would allow me the maximum, uh, slammage, as it were :lol: The dots represent holes and the line a slot, hopefully this would give me enough clamping to work like a regular clamp. It's hard to tell in the pictures but the slot and clamp would be between the two top tubes.

Suggestions?

OK, here's more.

A picture with a new seat compared to the old one. I think the small one looks too small. Having a functioning seatpost would make the bike a lot more comfortable. I'm not set on the fore and aft location but it will be over the seat tube rather than behind it. I think.

And the actual seat I would use, currently rusted to an old Raleigh :roll: It will clean up nice, it's a classy old Messinger.

And the way I would do the seat clamp, which would allow me the maximum, uh, slammage, as it were :lol: The dots represent holes and the line a slot, hopefully this would give me enough clamping to work like a regular clamp. It's hard to tell in the pictures but the slot and clamp would be between the two top tubes.

Suggestions?

Re: I dunno, she just flipped out! More props.

Is this bicycle for you? If it's for you, then a removable seat post really doesn't matter. I know when I ride a bicycle my seat is moved once and never moved again. So a suggestion is to just cut and weld a seat post to the frame and mount your seat to it. then you don't have to cut and try and make something work. Weld the seat post to the top tube just before the bottom bracket. Just a suggestion. I really like the way it is coming out. I wish I had seen this before I built my first swing bike, I would have done something like you have done.

Is this bicycle for you? If it's for you, then a removable seat post really doesn't matter. I know when I ride a bicycle my seat is moved once and never moved again. So a suggestion is to just cut and weld a seat post to the frame and mount your seat to it. then you don't have to cut and try and make something work. Weld the seat post to the top tube just before the bottom bracket. Just a suggestion. I really like the way it is coming out. I wish I had seen this before I built my first swing bike, I would have done something like you have done.

Re: I dunno, she just flipped out! More props.

when I welded my "new" BB on to the seat tube, I left about 1/2 inch of the seat tube on the "new" BB.

I cut about 3 inches off an old seat post as a sleeve and used it inside the seat tube to align both parts and to strengthen them.

this way I didn't have to notch the seat tube to the BB. 90 degree cuts on both parts.

I aligned the BB with straight edges across both the new and old BBs, and by critical eyeball.

good luck on your build. everything you do and plan just takes some common sense thinking ahead.

Personally I would never attempt using a stick welder on this thin tubing.

I don't have the skills. You are a better welder than I am using stick!

when I welded my "new" BB on to the seat tube, I left about 1/2 inch of the seat tube on the "new" BB.

I cut about 3 inches off an old seat post as a sleeve and used it inside the seat tube to align both parts and to strengthen them.

this way I didn't have to notch the seat tube to the BB. 90 degree cuts on both parts.

I aligned the BB with straight edges across both the new and old BBs, and by critical eyeball.

good luck on your build. everything you do and plan just takes some common sense thinking ahead.

Personally I would never attempt using a stick welder on this thin tubing.

I don't have the skills. You are a better welder than I am using stick!

Re: I dunno, she just flipped out! More props.

Dang it Dang it Dang it !!! Dang it! :lol: Well, it's on there now.

The seat needs to be adjustable cuz I'm vain. 1st, the bike looks better with the seat slammed, 2nd, I look better without my knees in my ears! Nah, mostly I want to be able to ride it comfortably but still be able to have the seat low for looks. It's kinda a technical exercise too, a little more detail.

Frikkin stick welder is a pain but I just couldn't listen to what everyone said to get a MIG. But that's cool. It works and for the same money I woulda had to buy a wicked crappy MIG. (now don't disillusion me with talk of buying used or anything like that :lol: )

Thanks for your suggestions and encouragement. I can sure use both. I'd whine if this were the place for it.

jerrykr said:when I welded my "new" BB on to the seat tube, I left about 1/2 inch of the seat tube on the "new" BB.

I cut about 3 inches off an old seat post as a sleeve and used it inside the seat tube to align both parts and to strengthen them.

this way I didn't have to notch the seat tube to the BB. 90 degree cuts on both parts.

I aligned the BB with straight edges across both the new and old BBs, and by critical eyeball.

Dang it Dang it Dang it !!! Dang it! :lol: Well, it's on there now.

The seat needs to be adjustable cuz I'm vain. 1st, the bike looks better with the seat slammed, 2nd, I look better without my knees in my ears! Nah, mostly I want to be able to ride it comfortably but still be able to have the seat low for looks. It's kinda a technical exercise too, a little more detail.

Frikkin stick welder is a pain but I just couldn't listen to what everyone said to get a MIG. But that's cool. It works and for the same money I woulda had to buy a wicked crappy MIG. (now don't disillusion me with talk of buying used or anything like that :lol: )

Thanks for your suggestions and encouragement. I can sure use both. I'd whine if this were the place for it.

Re: I dunno, she just flipped out! More props.

What problem are you having with the stick welder? Other than being noobie fumble fingers, I'm finding it seems to be sufficient for ratrod bikes with relatively thick tubing (though I have no basis for comparison). Seems to be more user error for me! And are you aware you can convert it into a TIG welder, with a few accessories? That was a selling point for me. I want to get competent with the stick first and then maybe I'll research the TIG conversion.

jackdaw said:Frikkin stick welder is a pain but I just couldn't listen to what everyone said to get a MIG. But that's cool. It works and for the same money I woulda had to buy a wicked crappy MIG. (now don't disillusion me with talk of buying used or anything like that :lol: )

What problem are you having with the stick welder? Other than being noobie fumble fingers, I'm finding it seems to be sufficient for ratrod bikes with relatively thick tubing (though I have no basis for comparison). Seems to be more user error for me! And are you aware you can convert it into a TIG welder, with a few accessories? That was a selling point for me. I want to get competent with the stick first and then maybe I'll research the TIG conversion.

Re: I dunno, she just flipped out! More props.

Here's what I did today. My new seat clamp works well. We'll see how it holds up to being ridden on. I cut the slot with a cut-off wheel but I cut to the side of my line instead of on the line. That's why it's off center relative to the holes :roll: I welded the clamp on on the other side.

I cut a hole in the bottom bracket for the seatpost. The seat tube is not centered on the BB but my hole was :roll: :lol: . It's all good. I think it will work well. I'm going to use a nicer bolt.

Jawon, it's just gumpy. It'll stick everything together well enough but I don't have nice looking welds yet. And they are possible with a stick welder. It is functioning perfectly, just noobie operator. They have been getting better for sure.

I'll be interested to see what you find out about TIG welders.

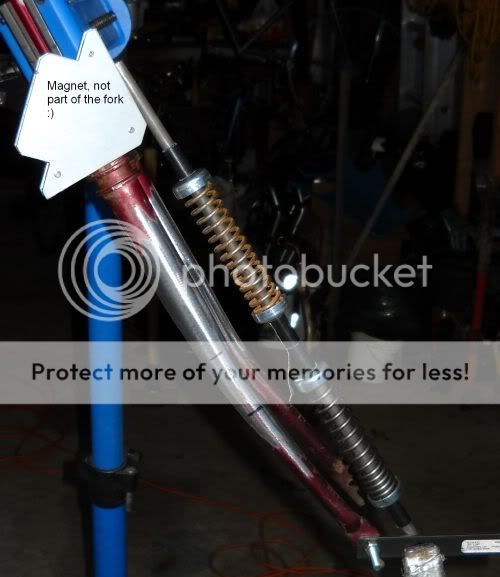

I'm on to the fork, we'll see how that goes. I'm going to be welding a bracket to the fork blades and a tube to that. I have a practice fork that's broken and some extra steel. I'm trying to figure out how to bolt the rockers to the forks, whether to drill new holes in the fork or use some "lawyer clips" or what. And so on, one step at a time. Having fun though.

I wish the tourists would go home.

Here's what I did today. My new seat clamp works well. We'll see how it holds up to being ridden on. I cut the slot with a cut-off wheel but I cut to the side of my line instead of on the line. That's why it's off center relative to the holes :roll: I welded the clamp on on the other side.

I cut a hole in the bottom bracket for the seatpost. The seat tube is not centered on the BB but my hole was :roll: :lol: . It's all good. I think it will work well. I'm going to use a nicer bolt.

Jawon, it's just gumpy. It'll stick everything together well enough but I don't have nice looking welds yet. And they are possible with a stick welder. It is functioning perfectly, just noobie operator. They have been getting better for sure.

I'll be interested to see what you find out about TIG welders.

I'm on to the fork, we'll see how that goes. I'm going to be welding a bracket to the fork blades and a tube to that. I have a practice fork that's broken and some extra steel. I'm trying to figure out how to bolt the rockers to the forks, whether to drill new holes in the fork or use some "lawyer clips" or what. And so on, one step at a time. Having fun though.

I wish the tourists would go home.

Re: I dunno, she just flipped out! More props.

Stick welders are really for building things with thick gauge metal, like bridges, tractors, you get the idea. It's not the best application for bicycles. A Mig is a bit more $ but not much more money than a stick welder, and is easier to weld with. I spent the money and got a Tig, cause down the road I knew I was going to weld other things besides Bicycles. I have fixed a few friends Aluminum trailers, alot of plow trucks, they are always breaking welds. Maine has to have a few plow trucks. 50$ there a 100$ here into your pocket.

I too went threw the whole what welder should I get for the right price. I fell on some money one day and ran strait to the welding store and bought a 2000$ Tig welder. I understand that not everyone has that kind of cash to spend. I couldn't go buy a new one right now, no way I could afford that. If you know this is something that you want to do, I would suggest getting a mig. If you get a mig then get one that you can upgrade down the road with a gas bottle. Make sure it is 220. If you get a 220 Mig welder with the option to upgrade the welder to have gas, then you can use your welder for more things. Make some side money fixing other peoples things like trailers, plow trucks, ext. 50$ there a 100$ here.

When it comes down to it, you are doing what you are doing with what you have and it all looks great to me. So maybe master the stick welding and when the time is right, upgrade.

Just keep building bicycles

Blue 8)

https://www.facebook.com/BluesBicycles?ref=hl

Jawon said:jackdaw said:Frikkin stick welder is a pain but I just couldn't listen to what everyone said to get a MIG. But that's cool. It works and for the same money I woulda had to buy a wicked crappy MIG. (now don't disillusion me with talk of buying used or anything like that :lol: )

What problem are you having with the stick welder? Other than being noobie fumble fingers, I'm finding it seems to be sufficient for ratrod bikes with relatively thick tubing (though I have no basis for comparison). Seems to be more user error for me! And are you aware you can convert it into a TIG welder, with a few accessories? That was a selling point for me. I want to get competent with the stick first and then maybe I'll research the TIG conversion.

Stick welders are really for building things with thick gauge metal, like bridges, tractors, you get the idea. It's not the best application for bicycles. A Mig is a bit more $ but not much more money than a stick welder, and is easier to weld with. I spent the money and got a Tig, cause down the road I knew I was going to weld other things besides Bicycles. I have fixed a few friends Aluminum trailers, alot of plow trucks, they are always breaking welds. Maine has to have a few plow trucks. 50$ there a 100$ here into your pocket.

I too went threw the whole what welder should I get for the right price. I fell on some money one day and ran strait to the welding store and bought a 2000$ Tig welder. I understand that not everyone has that kind of cash to spend. I couldn't go buy a new one right now, no way I could afford that. If you know this is something that you want to do, I would suggest getting a mig. If you get a mig then get one that you can upgrade down the road with a gas bottle. Make sure it is 220. If you get a 220 Mig welder with the option to upgrade the welder to have gas, then you can use your welder for more things. Make some side money fixing other peoples things like trailers, plow trucks, ext. 50$ there a 100$ here.

When it comes down to it, you are doing what you are doing with what you have and it all looks great to me. So maybe master the stick welding and when the time is right, upgrade.

Just keep building bicycles

Blue 8)

https://www.facebook.com/BluesBicycles?ref=hl

Re: I dunno, she just flipped out! Fork? Maybe.

Looks Killer!!! Like the forks a lot :lol: :lol: :lol: :lol: :lol: :lol:

I'm stumped on how you are going to make this work. I like that. My anticipation makes me go hmmmmmm

Thank God for Bondo

jackdaw said:

Looks Killer!!! Like the forks a lot :lol: :lol: :lol: :lol: :lol: :lol:

I'm stumped on how you are going to make this work. I like that. My anticipation makes me go hmmmmmm

Thank God for Bondo

Re: I dunno, she just flipped out! Fork? Maybe.

Yeah iven, I just cut the legs off some donor bike forks and they come right out.

PWAV, I have not seen a fork like it. I hope it works! :lol: The blue fork is a practice fork, of course. I wanted to see what welding a thick piece to a relatively thin tube would be like. I'm going to practice it again. This is not a weld I want to have fail!!

I think that, like member Jawon did, I'm going to leave my welds as they are. Do my best with the grinder and sandpaper and let them be what they are. It will also make it easier to see if they're coming apart!

Thanks for your help with the welding, I'm getting better.

I promised myself I would get all frame and fork mods done before I started another project. But geez, am I impatient.

iven said:starting to look very intresting... those just cheapo mtb fork srpings? :0

Yeah iven, I just cut the legs off some donor bike forks and they come right out.

PWAV, I have not seen a fork like it. I hope it works! :lol: The blue fork is a practice fork, of course. I wanted to see what welding a thick piece to a relatively thin tube would be like. I'm going to practice it again. This is not a weld I want to have fail!!

I think that, like member Jawon did, I'm going to leave my welds as they are. Do my best with the grinder and sandpaper and let them be what they are. It will also make it easier to see if they're coming apart!

Thanks for your help with the welding, I'm getting better.

I promised myself I would get all frame and fork mods done before I started another project. But geez, am I impatient.

Re: I dunno, she just flipped out! Fork? Maybe.

Cool concept on the forks!!! Looks pretty cool. 8) 8)

Cool concept on the forks!!! Looks pretty cool. 8) 8)