Congratulations on the birth of your daughter!

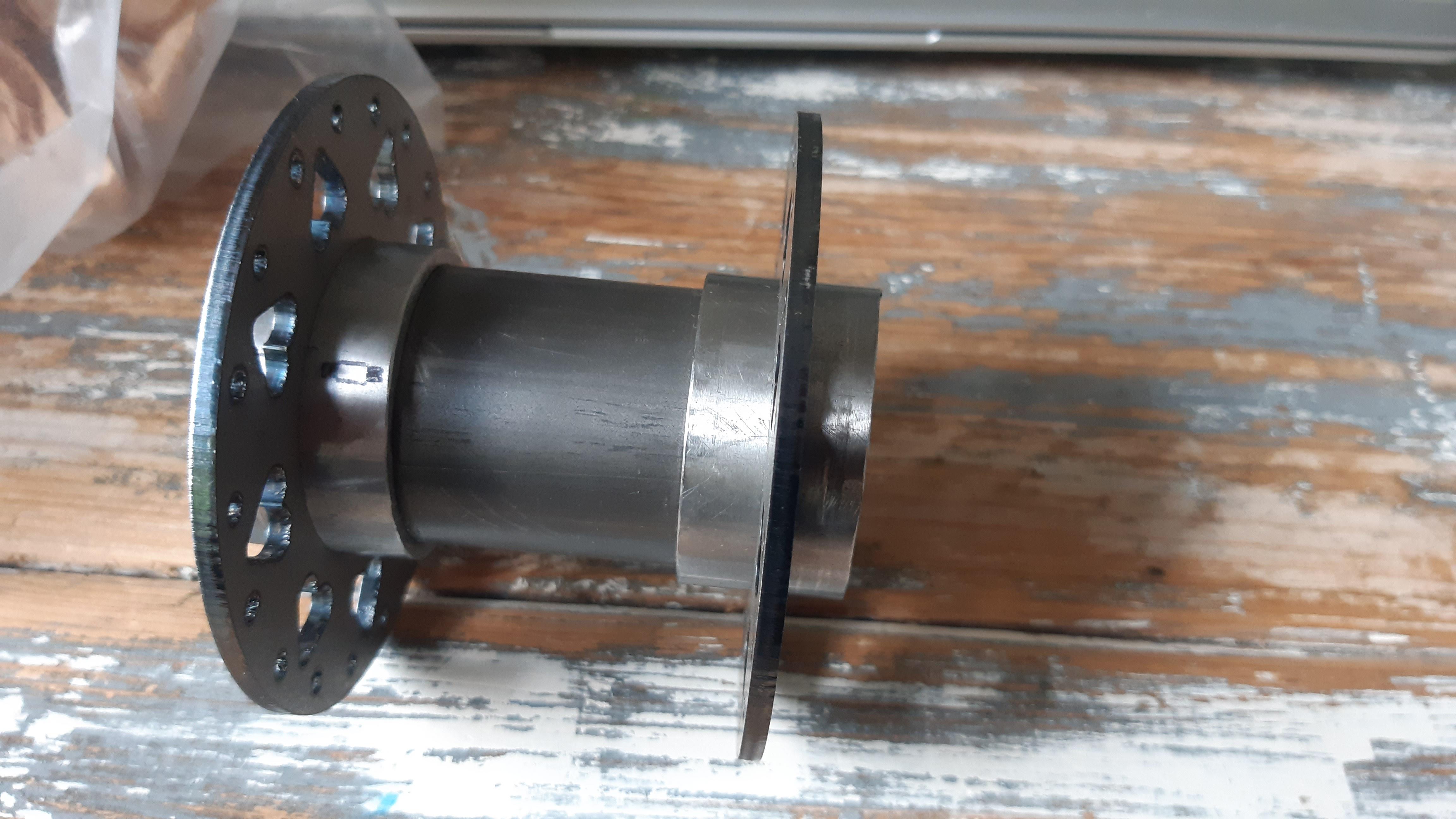

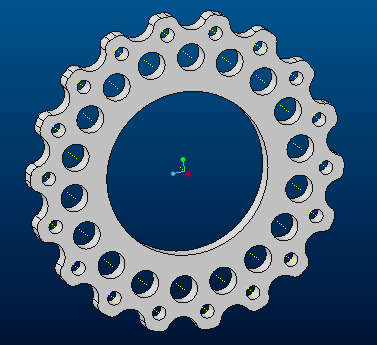

Great find on the frame! And those flanges sure came out sweet!

Great find on the frame! And those flanges sure came out sweet!

Not exactly, we had a few check-ins from the midwife, but basically after we left the hospital, we were on our own. Family support, of course, but nothing like help with chores and feeding. That's why I thought you might have your hands full, around here that's up to Vader.Is this also common in the US or Canada? Where you get this kind of help the first week?

I never thought to ask for bike helpI could not convince the lady to make a mockup with the chopper frame

In the US (for me anyhow) it involves a visit from at least one of the grandmother's for the first week or so. Sometimes the two grandmother's could be convinced to come consecutively and extend that out. But that was just our experiences. My mom has 32 grandchildren and 8 great grandchildren. She's quite doting and fond of the babiesThanks a lot guys! Its kinda busy with two kids now, but everyone will have to get used to the Chopper.... ehh to the baby

Moeder is doing great and really taking good care of Thura. I am taking care of our two year old daughter most of the time now.

During the "kraamweek" we had help from a "kraamverzorgster". A nice lady that helps with the baby's and moms health (checking weight, temperature and milk intake) and with some chores around the house. This is normal in the Netherlands where you get help for a week.

Unfortunately I could not convince the lady to make a mockup with the chopper frame

I'll make a thread soon.

Is this also common in the US or Canada? Where you get this kind of help the first week?

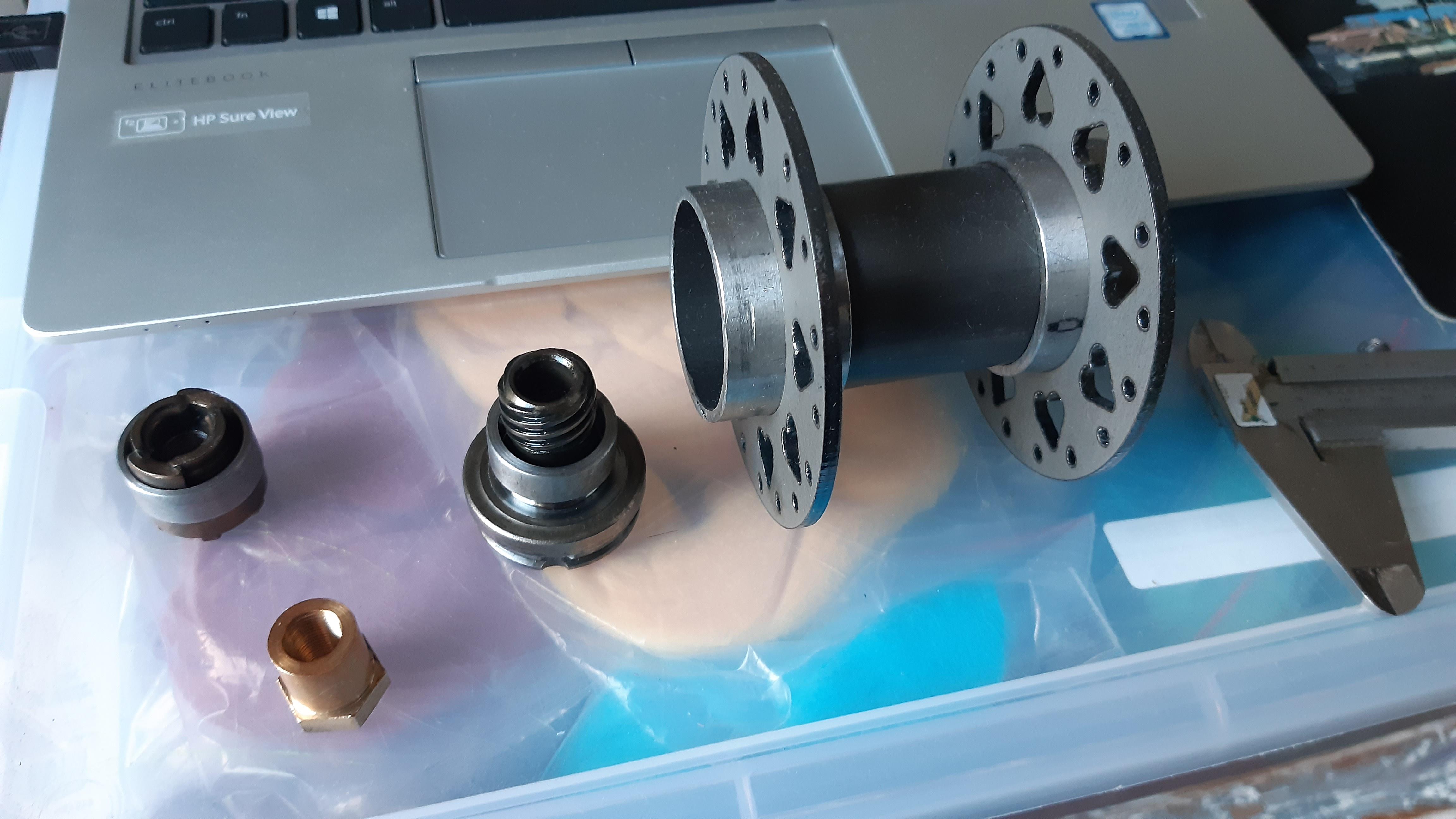

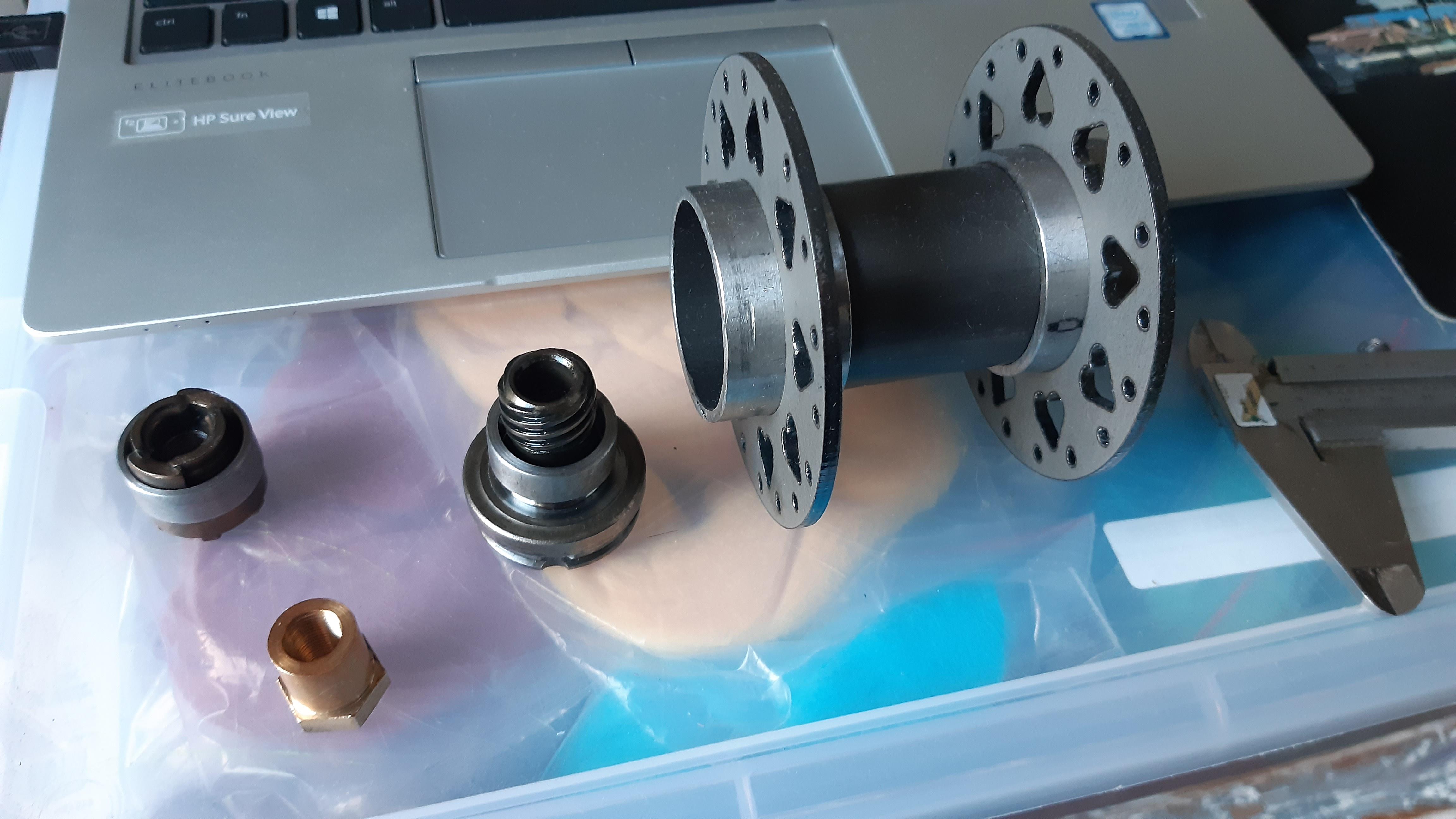

I did have some time to look for junk on the interwebs and found some hubs for 2 euros. They are from kids bikes, but almost new!

One is a 28 hole 1985 F&S Torpedo hub.

The other a F&S replica by Romet with less holes (I think a Polish buildoff participant mentioned this brand of hub/bike).

I ordered two extra hub flanges for this hub, so its 36 hole too! I can bolt or rivet the flanges or that hub.

And I could not resist buying a 50's US wheelset with bendix hub: (Uncommon in the Netherlands)

Bought it from "bikestoremember.nl". They have some "New Departure model D's" with skip tooth as well. Including complete wheelsets.

I don't know for which build I will use this set, maybe I will take a bike apart and build something new.

Thinking to take apart my green Electra RS Klunker and put this set on the frame and store it for a future buildoff....

Use the 26 inch Klunker wheelset for the chopper....

Also toying with the idea of throwing the chopper in the yard (with grease inside the frame) for a rat build. The frame is almost the same as the Nirve Cannibal/Switchblade.

In the coming months I will have time for a mockup and rearreangement of parts/bikes.

Thanks again!

That seems awesome as well. We did not ask for presents, but food and meals, because you are quite busy that first period.In the US (for me anyhow) it involves a visit from at least one of the grandmother's for the first week or so. Sometimes the two grandmother's could be convinced to come consecutively and extend that out. But that was just our experiences. My mom has 32 grandchildren and 8 great grandchildren. She's quite doting and fond of the babies

Canada is hardcoreNot exactly, we had a few check-ins from the midwife, but basically after we left the hospital, we were on our own. Family support, of course, but nothing like help with chores and feeding. That's why I thought you might have your hands full, around here that's up to Vader.

I never thought to ask for bike help

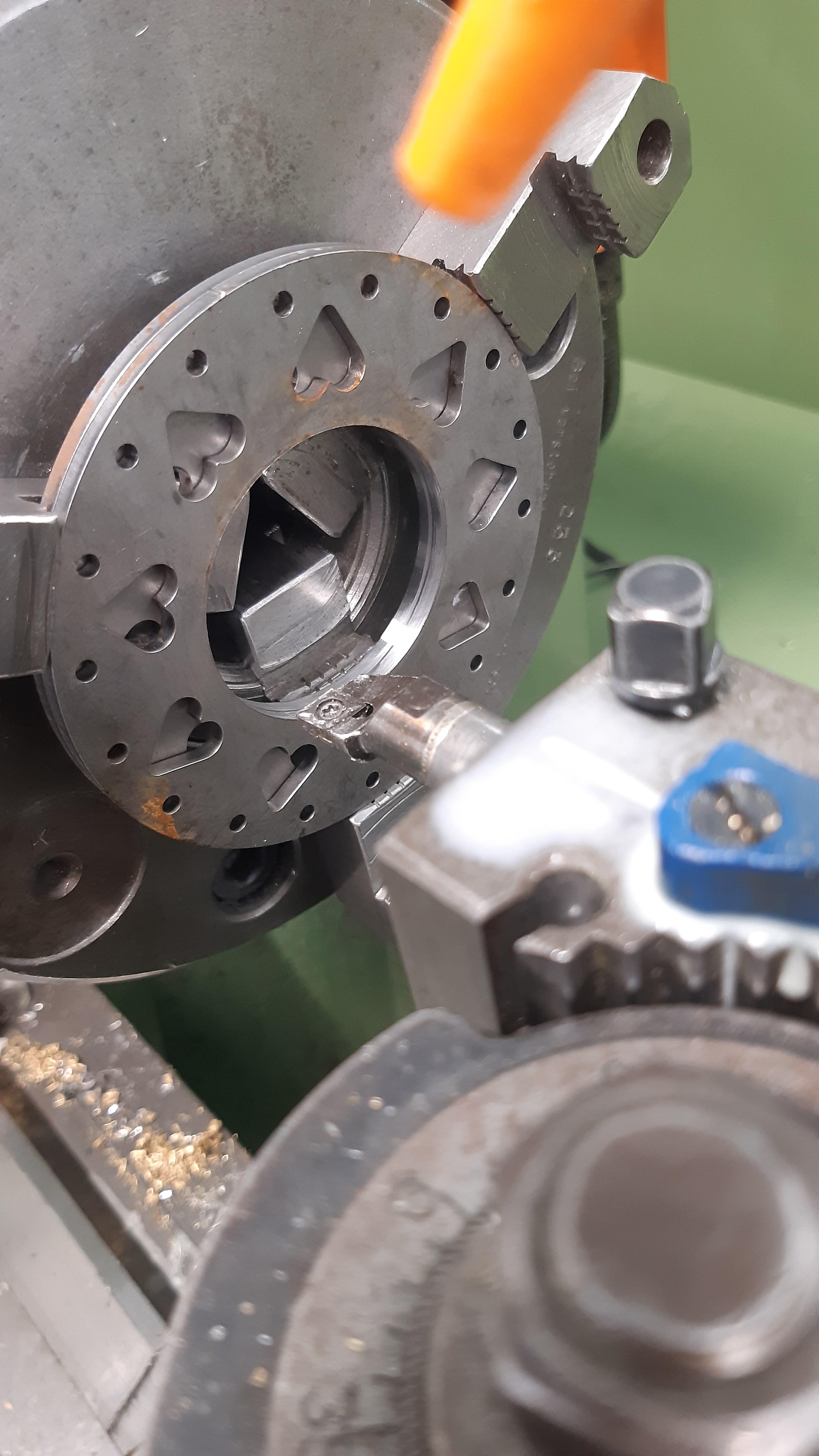

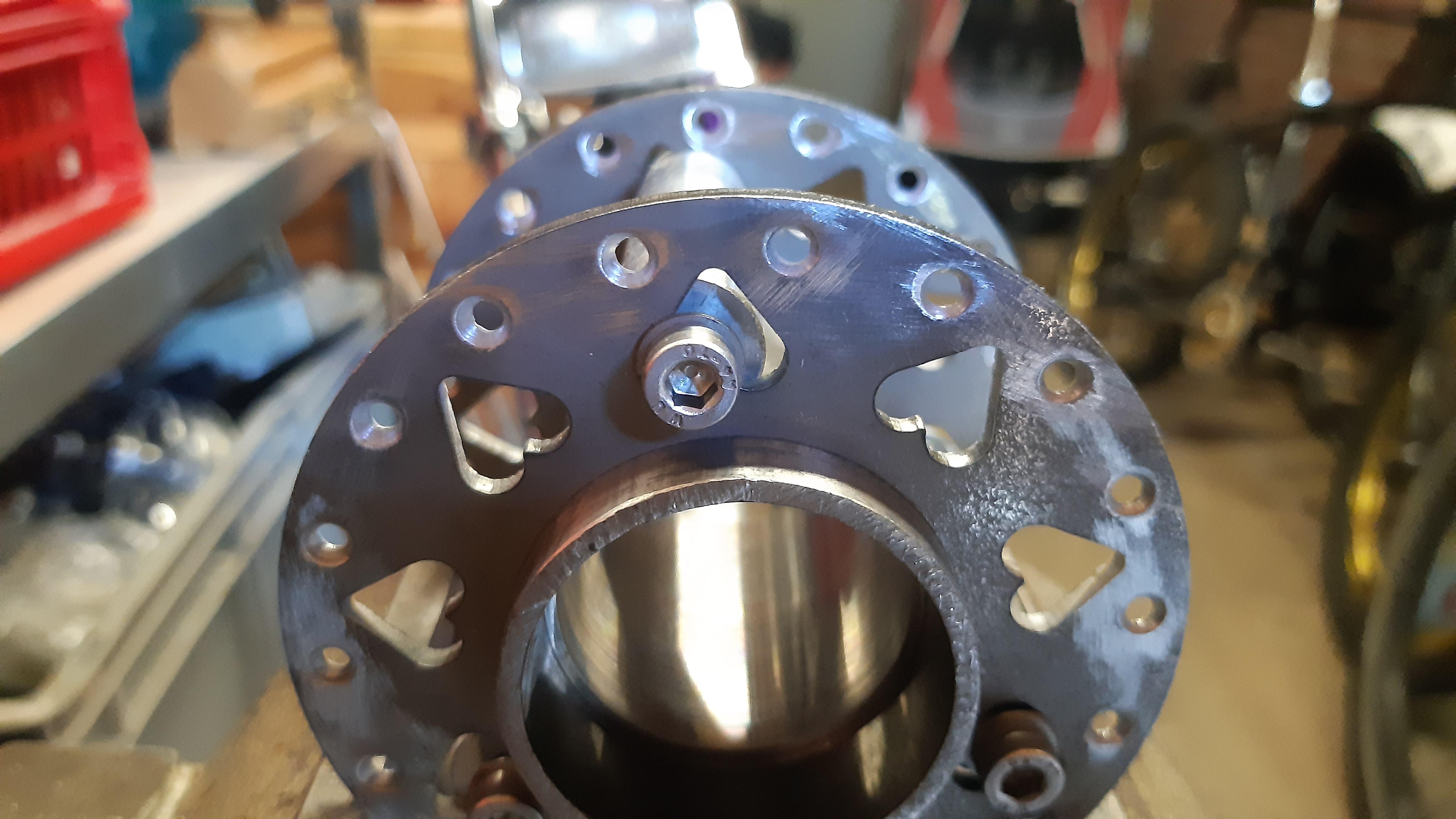

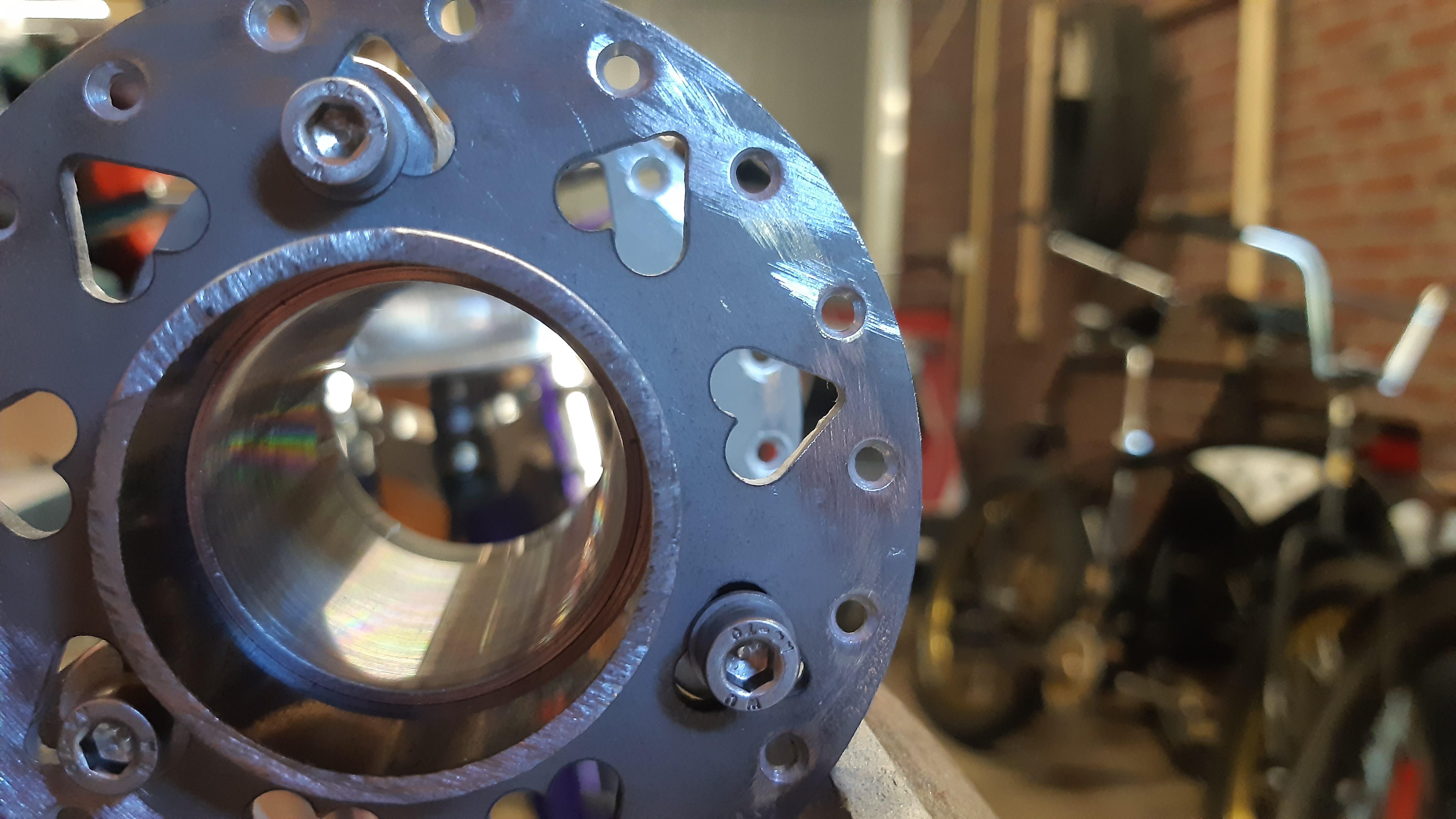

only slightly brushed the outside of the hub flanges so I could get a 'surface' to press the flanges on.

only slightly brushed the outside of the hub flanges so I could get a 'surface' to press the flanges on.

It is a good solid design, but on the other hand, the "1907 New Departure patent on a coasterbrake hub with that multi-cycle threaded clutch" (like the Shimano CB-E110) is even more simple and it is solid. You just gotta keep the water and rain out.Nice work on the hubs!

Those Romet rear hubs are actually made by a Czech company, Velosteel, and I am currently stripping down an older version from a Ukraine bicycle. I have no idea how a Fichtel & Sachs design ended up being so popular here, though.

I finally caught up with this one, just because I love the decorative flange work. I don’t own a lathe, so no chance of me turning out stuff like this right now.

I have some bicycle hubs like this where you can press the flanges on and off, but I’m not sure how I could get the spoke indexing correct if I did that. Did you make some kind of indexing tool?

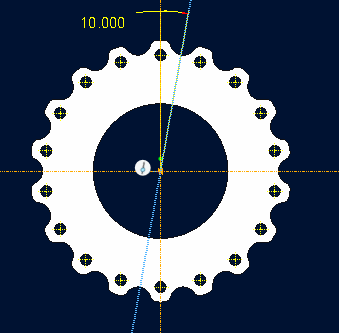

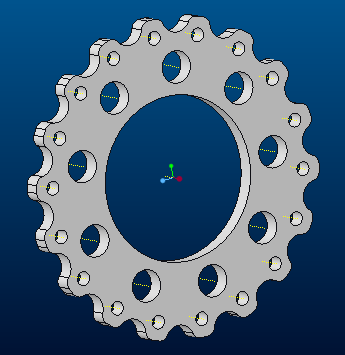

What do you think about the laser cutting versus waterjet cutting on parts like this?

I’ll have to send out a DXF or similar and have them cut.

I am from the days when we had to draw the stuff on mylar with ink, and then an “electric eye” would follow the pattern, and cut your parts with an acetylene torch. It was all big industrial stuff.

I wasn’t doing any delicate parts like this, so I don’t have a clue about lasers and water jets, and only one little experience with EDM.

All the light gauge work I ever drew was Stamped out on an AMADA turret press. I did steel cabinetry & little parts for vending machines.

Thank you again Ulu!That’s amazing! And it’s not a Skiptooth either. These were from a derailleur bike?

The English bicycle I just did had those woven cloth rim liners as well. They have little metal buckles on them.

I believe skiptooth was only popular in US. In Europe skiptooth was around when chains were still block chains and not roller chains, and as soon as technology shifted to roller chains around 1910's they switched to regular teeth. While in US they continued with skiptooth to provide some old and new standard compatibility.That’s amazing! And it’s not a Skiptooth either. These were from a derailleur bike?

The English bicycle I just did had those woven cloth rim liners as well. They have little metal buckles on them.

Now I’m wondering what the manufacturer called it.I call it a heat sink.

heat sink

noun

: a substance or device that absorbs or dissipates especially unwanted heat (as from a process or an electronic device)

And I can't wait to see what you come up with, Bart

They refer to it as a cooler. Might be because makes a standard Shimano hub, you know, coolNow I’m wondering what the manufacturer called it.

Enter your email address to join: