Heading into the home stretch! I've been pretty busy with the bike so here's a few updates. But first a glimpse into my pea-brain:

"Under no uncertain circumstances am I going to pinstripe the rear fender. No way. The "tool" I bought for striping was garbage. The chainguard was nearly a disaster. I've spent too much time stripping, painting, sanding and polishing that fender to screw it up with a stupid stripe. Don't care. Not going to happen."

I just couldn't NOT do it. I'm happy with how it turned out–it ties the fender into the front one and the frame without being perfect to either. I was afraid of having the arc be wrong or not sealing the tape well enough, etc, but low and behold I have a stripe. One on each side actually. I also separated the two-tone paint with white mimicking the front fender. Turns out the stripes were nothing compared to the fender brace.

I wanted to use a matching Shelby curb-feeler brace that I had on the front. They are nowhere near the same shape or dimensions of the Monark fender. I ended up cutting the brace down the middle, reshaping the arc of the part that goes under the fender to match the inner diameter (and clear the tire), drilling new holes to match what was already drilled in the fender, and then shortening each brace around 3/4". All the while I have no idea if they wheel is going to be centered in the fender, front to back or side to side, when it was all said and done.

But by some miracle

And it doesn't rub. Not too shabby for a guy with a dremel and a cordless drill.

Another piece of the puzzle I've been working on is the shifter. The rear hub is an 8-speed and I have the grip shift that goes with it. I found the tutorial in the "how to" section on making a cover that blends a little better with the rest of the bike. I followed it, with a few tweaks. One of the first things I did was cut down the shifter:

See that little lip on the the end there? Turns out that's what keeps the shifter from exploding when you down shift. It literally pushes itself apart. Now I can't decide if it's more stupid or stubborn, but I was determined to fix this without buying a new shifter. Here's what I came up with:

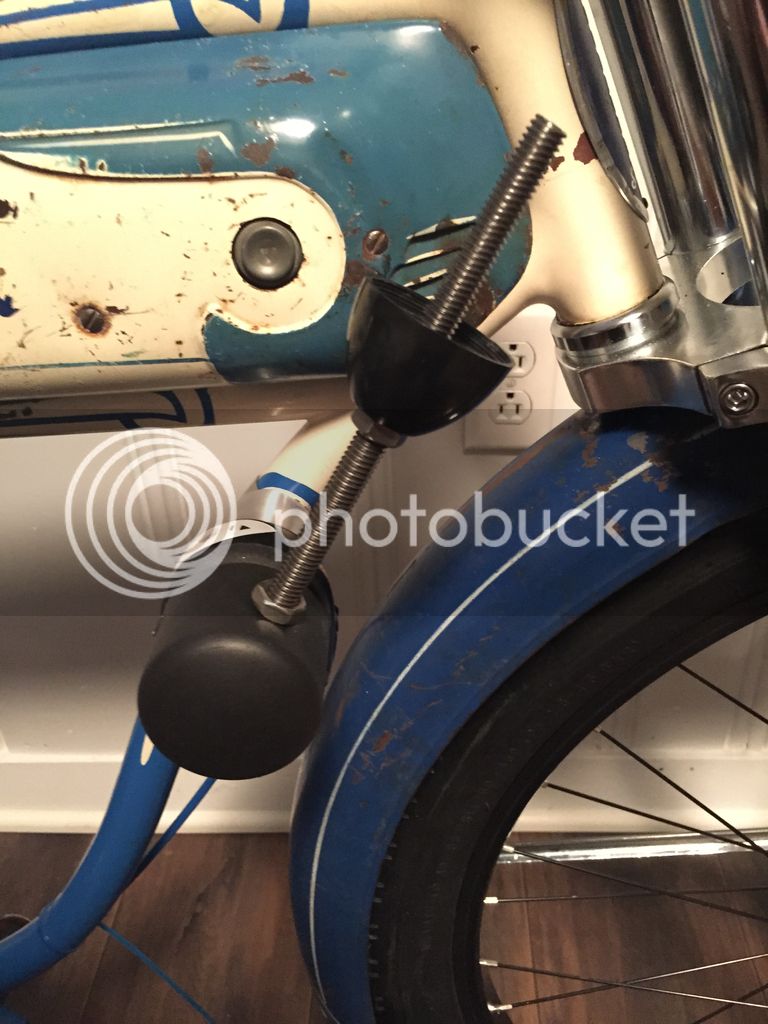

A marine compression plug, a pronged T-nut, and a bolt with a very flat head (after all I wanted this to be narrower overall). Had to cut the plug down (hacksaw):

And here is my recreated "lip" holding the gripshift onto the post attached to the frame.

Before:

After:

Still kept everything compact enough to use the PVC cap (shown above) for a shifter cover. Here is where I diverged from the original tutorial. The original design is apparently prone to stripping out, so I added two holes for threaded set screws.

Add in the third hole for my shift lever and hopefully I've got something will last a while. Got it roughed up and ready for some Rustoleum rubber-dip paint.

Lastly here's a couple gratuitous chainguard shots. In addition to my vinyl decal, I added the original design Schwinn waterslide decal, and my infamous pinstripes on the feather edging.

I'm really happy with the transformation from the original "nice, but..." chainguard to one worthy of this build.

Lastly as the 4th of July rolls in I want to extend my gratitude to the servicemen/women on this site, and throughout the world, for your service to this country. Happy Independence Day, all!