TV in the living room quit working Friday. As with most modern technology, we figured it would cost more to fix than to replace. Youngest son who's still living at home decided he wanted to buy a new TV too. I also bought a new jig saw too while in town!

I helped my son hang his TV on the wall in his room, so no bike time after work, but that's okay because Eric won't always live with us and I might not get to see him much when he moves out. Saturday my wife and I threw caution (and masks and gloves) to the wind and drove the 2.5 hours to visit our oldest son and his wife and their new baby. Finally got to see the new grandson again! Again, more fun than the build off! LOL

So this afternoon, with my wife doing what she wanted to for Mother's Day (play in the dirt in the garden) I worked on the Green Machine.

Used the new jig saw to cut out a better fitting piece to be the center piece of the tank. Then marked and drilled the holes for the headers. Yes, headers. More hot rod than manifolds! LOL

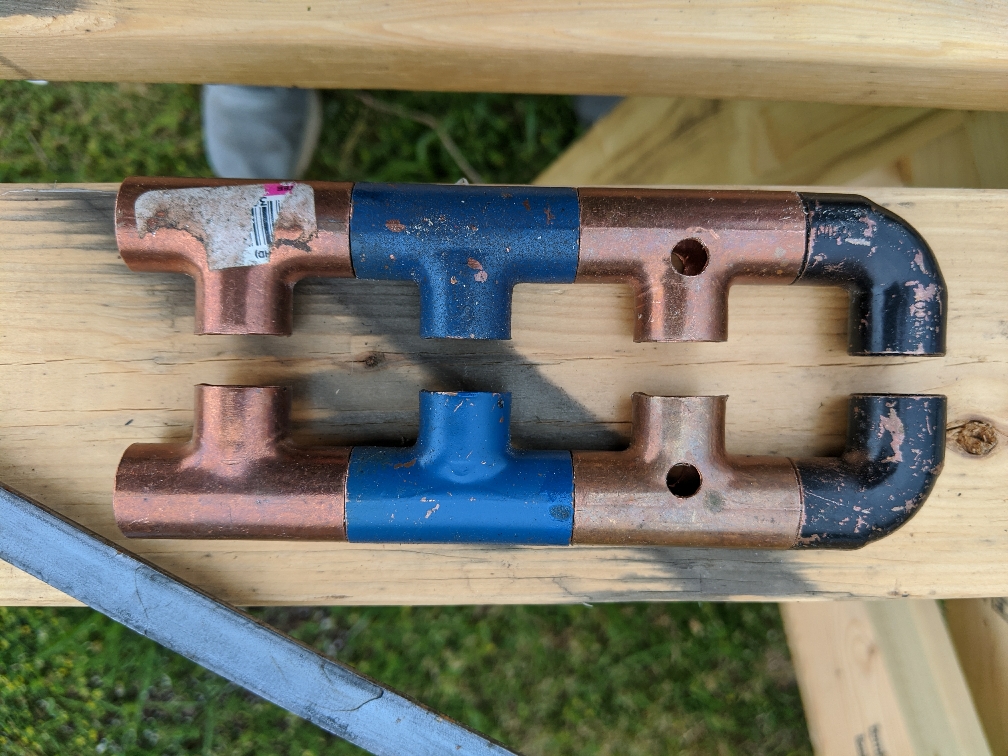

Since this is the GREEN machine, I recycled as many 1/2" copper pipe fittings as I could find.

Not sure if I will JB Weld the pieces together or solder them. I think soldering would be more old school, but will require more paint removal.

I'll be adding additional pieces of wood to buils up the tank, but it will be cut away around the headers. Thinking maybe two more layers of pine board on each side, or maybe some 1/2" plywood and one piece of pine per side.

I'm using some 45 degree elbows to make a jog in the exhaust pipes to give more room around the rear tire. Not sure if the tail pipe tips with be left straight or recut at an angle.

Here it is down off the "rack" and sitting good ol' terra firma.

Bird's eye view of the headers...