Shaped the plug for the front light today.

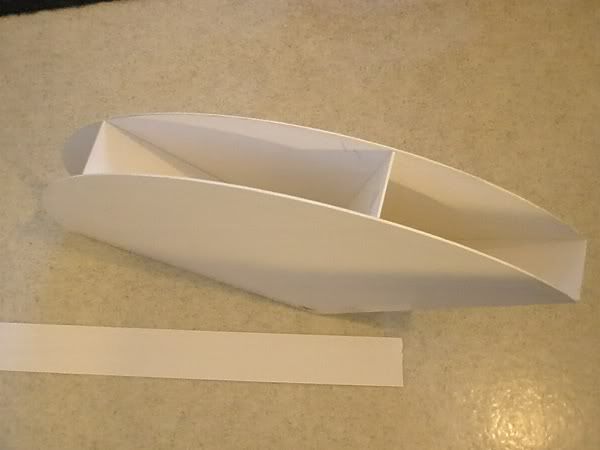

Looks like this now:

I'll cover it with plastic tape before I make the fiberglass shell, so the rough texture and little uneven spots will be smoothed out.

I think what I'll do some work on the next time I get a couple of minutes to spare :roll: are cardboard templates for the fenders. Then I can glass the front light shell and fenders at the same time, and also I need to have the fenders glassed before I can start shaping the foam on the frame...yup, that's my plan.

That's all for now,

take care everybody!

Looks like this now:

I'll cover it with plastic tape before I make the fiberglass shell, so the rough texture and little uneven spots will be smoothed out.

I think what I'll do some work on the next time I get a couple of minutes to spare :roll: are cardboard templates for the fenders. Then I can glass the front light shell and fenders at the same time, and also I need to have the fenders glassed before I can start shaping the foam on the frame...yup, that's my plan.

That's all for now,

take care everybody!