You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what is your favorite sprocket

- Thread starter barnbikes

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

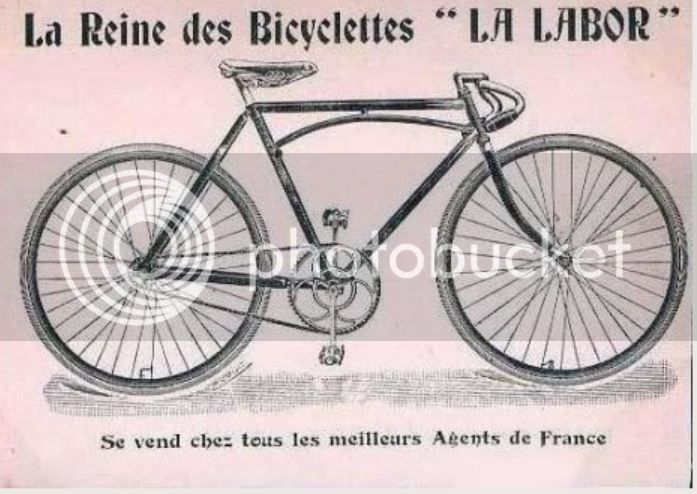

Found this pic in a magazine last night, sorry for the blurry photo but it was super small, looks like a cool chainring though!

Luke.

Luke.

How much are these ball park? Also, I'm pretty sure you meant 3 kW rather than 3,000 kW, coz that would just be...wow. I don't even want to think about it. We've got a 5 kW and 2.5 kW CO2 we're using to make nanotubes.

How much are these ball park? Also, I'm pretty sure you meant 3 kW rather than 3,000 kW, coz that would just be...wow. I don't even want to think about it. We've got a 5 kW and 2.5 kW CO2 we're using to make nanotubes.

$0.50 a tooth plus shipping.

You are correct it is 3 kw or 3,000 watt.

$19.99

Electra Glide Wall Decal 2ft Long Sport Harley Davidson Bike Motorcylce Sticker Man Cave Garage Boys Room Decor

FatCat Wall Graphics

$19.99

Top Brass Bicycle/Motorcycle Chain Picture Frame 5" X 7" Photo - Faux Bike Chain

Old River Outdoors (USA Merchant)

$63.46

Motorbike Parts Front & Rear Brake Pads Kit For EXC300 04-05 MXC300 04-06 EXCF250 06-07 SX250 03-08 SX250 2T SXF250 4T 09-14

zhengzhoushigedakewangluokejiyouxiangongsi

$19.99

Old River Outdoors Bicycle/Motorcycle Chain Picture Frame 4" X 6" Photo - Faux Bike Chain

Old River Outdoors (USA Merchant)

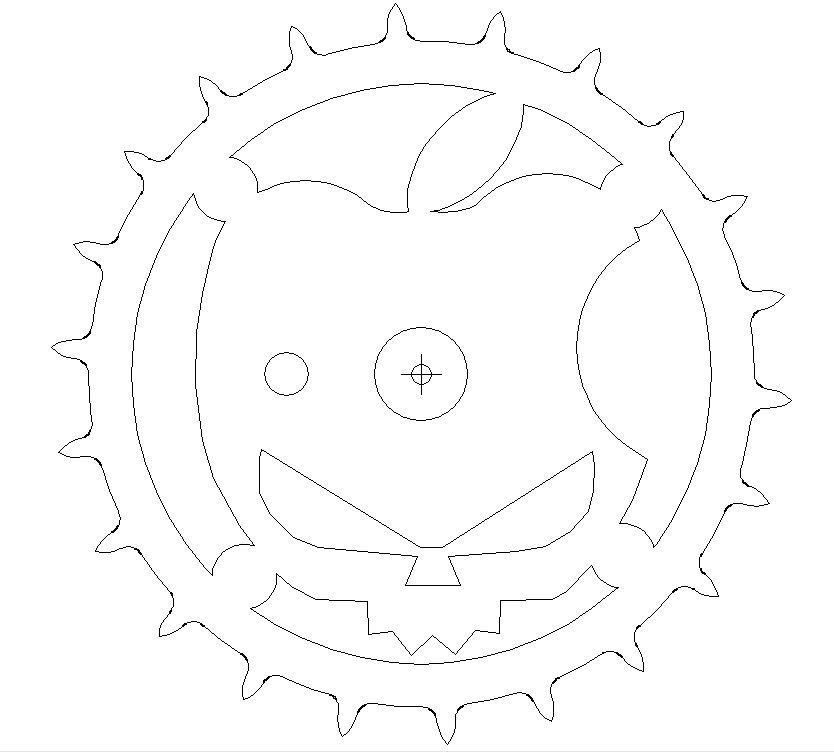

That definitely needs a bash bar of some kind...

Carl.

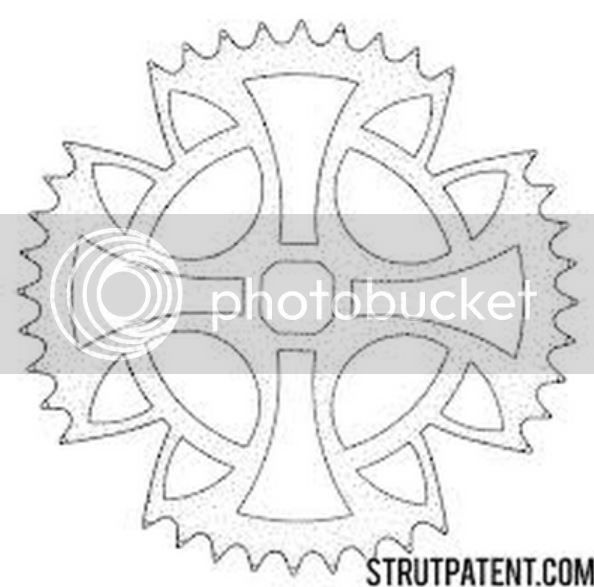

Put me in line bro when you get to designing! Might want to raise the prices a little from the vintage ad! I'm sure you could come up with something I will want with my logo on it.

don't listen to him, the ad prices are fine.

Put me in line bro when you get to designing! Might want to raise the prices a little from the vintage ad! I'm sure you could come up with something I will want with my logo on it.

If I go forward with the guard project it will be an assembly required item. Basically you would get the outer plate with top and bottom flats formed and the front curve would have to be welded on by buyer.

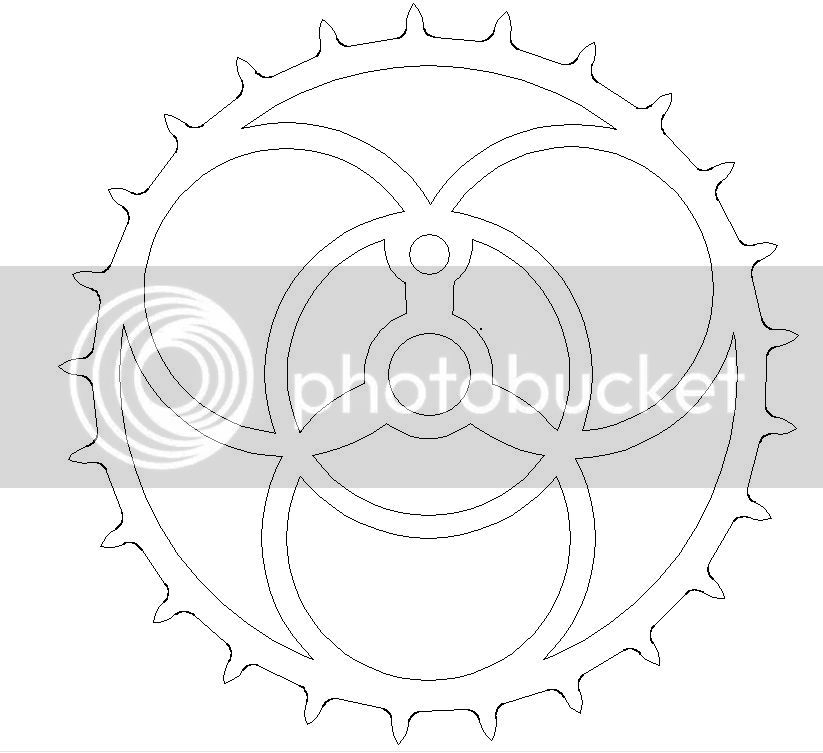

Reminds me a bit of the biohazard symbol

The Renaissance Man

__CERTIFIED DIVER__ (Open Water & Open Dumpster)

Staff member

Moderator

Pro Member

That takes way too long to produce one sprocket. I for one, just don't have that kind of time to wait. Obviously out dated technology.

Wow! That is awesome to watch!

Luke.

Luke.

Do these sprockets need to be hardened at all after they are cut? I run a laser cutter as well and have thought about making a custom one for my bike, but I was concerned that the sprocket wouldn't be strong enough and would get worn down too quickly by the chain. I considered using hardened plate to begin with, but I thought the heat from the laser cutting would soften the edge of the material slightly, so the sprocket would need to be heat treated afterward anyway.

Also, do I need to have a beveled edge like a stock chainring? Maybe I'm just thinking too much into it.

Also, do I need to have a beveled edge like a stock chainring? Maybe I'm just thinking too much into it.

The Renaissance Man

__CERTIFIED DIVER__ (Open Water & Open Dumpster)

Staff member

Moderator

Pro Member

Do these sprockets need to be hardened at all after they are cut? I run a laser cutter as well and have thought about making a custom one for my bike, but I was concerned that the sprocket wouldn't be strong enough and would get worn down too quickly by the chain. I considered using hardened plate to begin with, but I thought the heat from the laser cutting would soften the edge of the material slightly, so the sprocket would need to be heat treated afterward anyway.

Also, do I need to have a beveled edge like a stock chainring? Maybe I'm just thinking too much into it.

I was wondering the same thing. Something tells me that typical big box chainrings are not hardened steel, but the beveled edge does seem like it would be important.

I don't think they're hardened, as you can cut and weld on them as if they're mild steel. Just regular (or you could do cromoly) steel, I suspect.