Re: Villiers board tracker WILL BE SET ON FIRE!

You're going to need a jack shaft for your four stroke engine. Your ratio should be closer to 10:1. 4.4:1 is way off. If you were running a two stroke, high rpm motor, you can get away with a direct drive clutch to rear sprocket. Your clutch engages around 2,300 rpm and your top rpm will be around 4,200 rpm. Trust me. With a 26" wheel, and a small four stroke engine, you want a ratio around 10:1. I'm not just talking, I've actually built it.

Buy this 5/8" jack shaft kit for $29.00. It includes everything you need including the high rpm bearings.

http://www.mfgsupply.com/m/c/AZ1826-10.html

Buy a 9T or 10T, 5/8" bore bicycle sprocket here for $15.00.

http://www.sickbikeparts.com/catalog/pr ... kf5ma15ou2

Buy a #35 28T, 5/8" bore sprocket here for $24.00

http://www.mcmastercarr.com

Part number 6236K108

Run a #35 chain on your left clutch side. You can buy #35 chain from http://www.mcmastercarr.com

If you bought a #41 chain clutch, trade it in for a #35 chain clutch. This will keep your sprockets smaller on the left side of your bike.

Run a .500" pitch bicycle chain on your right hand side.

You will be up and running in about $70.00 and two hours of fabricating.

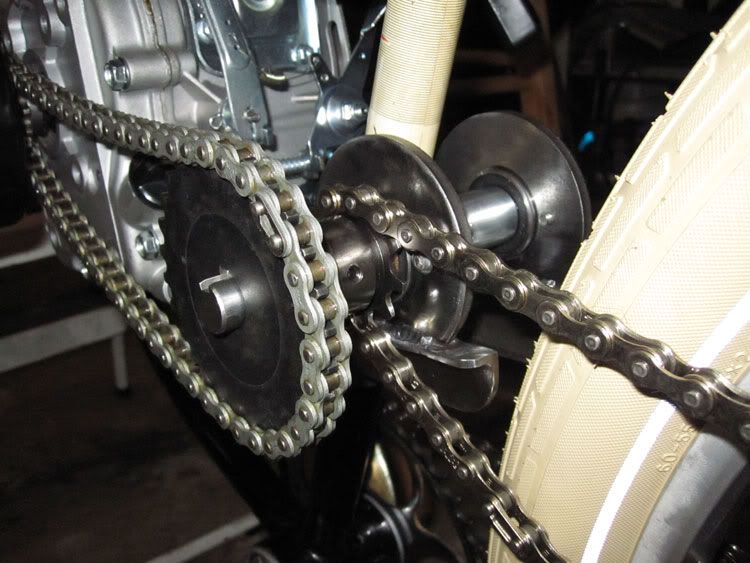

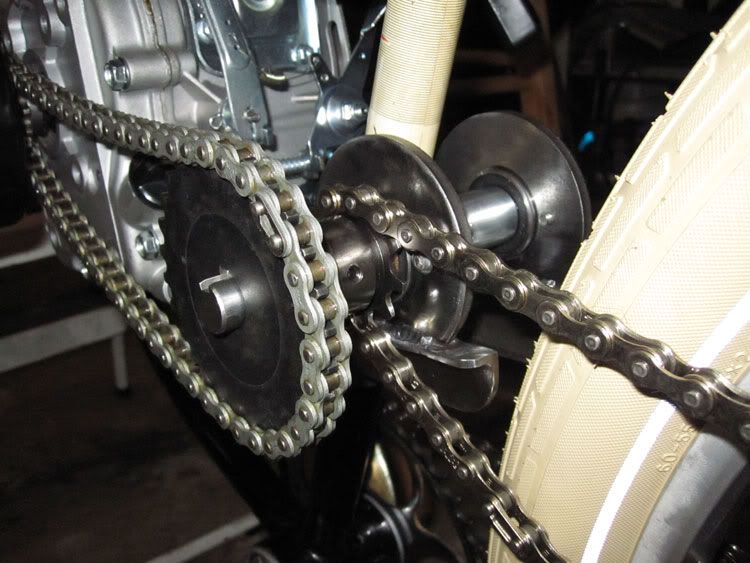

This is what it will look like, only you will have a sprocket on the left and right side of your crank.

stocksucks said:Thanks for all the input guys.

I'm gonna try to drive a direct chain from the cent clutch to the wheel.

I've spent a bit of money on this and I'm allways aiming at using things that lay around. Also, I'm thinking of buying a V2 engine for a next build so I've gotta save...

As you know, I've got a 10 teeth sprocket on the clutch an a 44 teeth sprocket on the wheel. Ratio 4.4

What do you think?

Thanks a lot

You're going to need a jack shaft for your four stroke engine. Your ratio should be closer to 10:1. 4.4:1 is way off. If you were running a two stroke, high rpm motor, you can get away with a direct drive clutch to rear sprocket. Your clutch engages around 2,300 rpm and your top rpm will be around 4,200 rpm. Trust me. With a 26" wheel, and a small four stroke engine, you want a ratio around 10:1. I'm not just talking, I've actually built it.

Buy this 5/8" jack shaft kit for $29.00. It includes everything you need including the high rpm bearings.

http://www.mfgsupply.com/m/c/AZ1826-10.html

Buy a 9T or 10T, 5/8" bore bicycle sprocket here for $15.00.

http://www.sickbikeparts.com/catalog/pr ... kf5ma15ou2

Buy a #35 28T, 5/8" bore sprocket here for $24.00

http://www.mcmastercarr.com

Part number 6236K108

Run a #35 chain on your left clutch side. You can buy #35 chain from http://www.mcmastercarr.com

If you bought a #41 chain clutch, trade it in for a #35 chain clutch. This will keep your sprockets smaller on the left side of your bike.

Run a .500" pitch bicycle chain on your right hand side.

You will be up and running in about $70.00 and two hours of fabricating.

This is what it will look like, only you will have a sprocket on the left and right side of your crank.