So in the design I'm sorta basing my design on, the gent used a couple of sheave wheels as a faux oil tank. He used a large sheave wheel as the main part then used a smaller sheave wheel to run a chain around. It looks like he used a tractor pin in the middle. Looks like this on the left side...

And this on the right...

Pretty darned clever if you ask me!

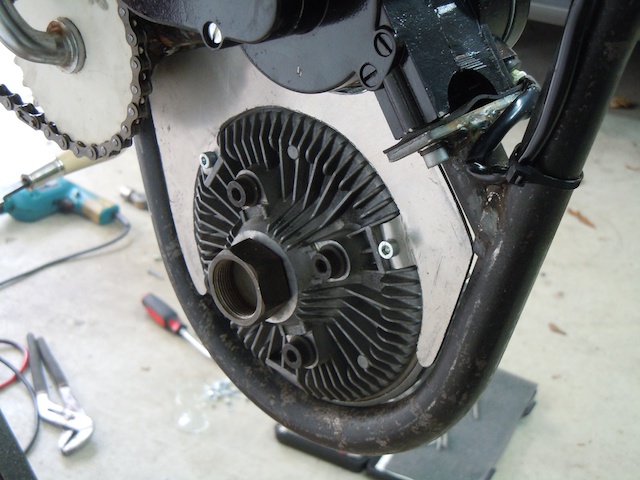

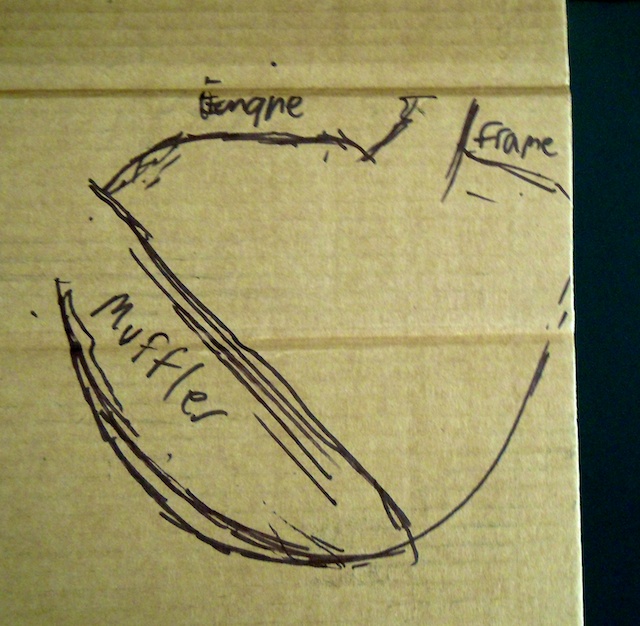

But I want to do something a little more representative of the period. Not sure what yet, but I'm thinking... So I took a piece of cardboard and traced out the opening. Here's the opening below the engine...

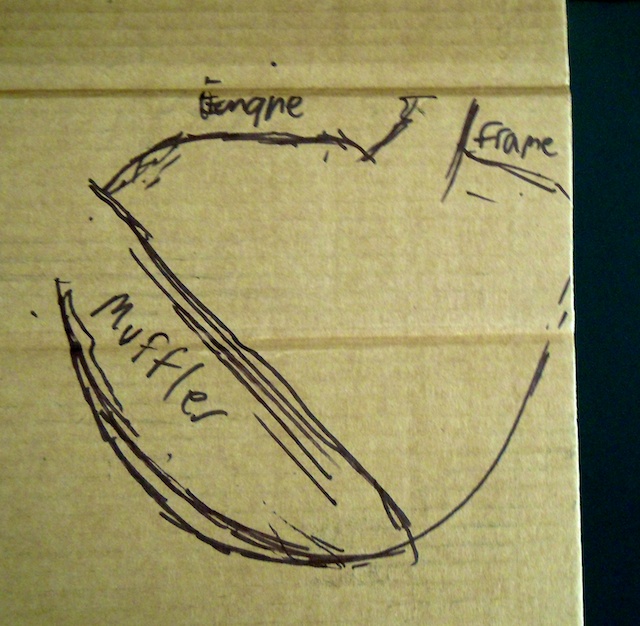

And here's my tracing...

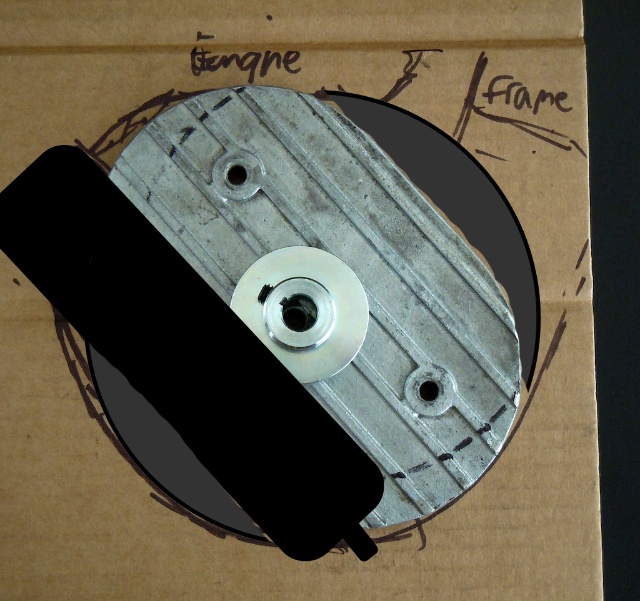

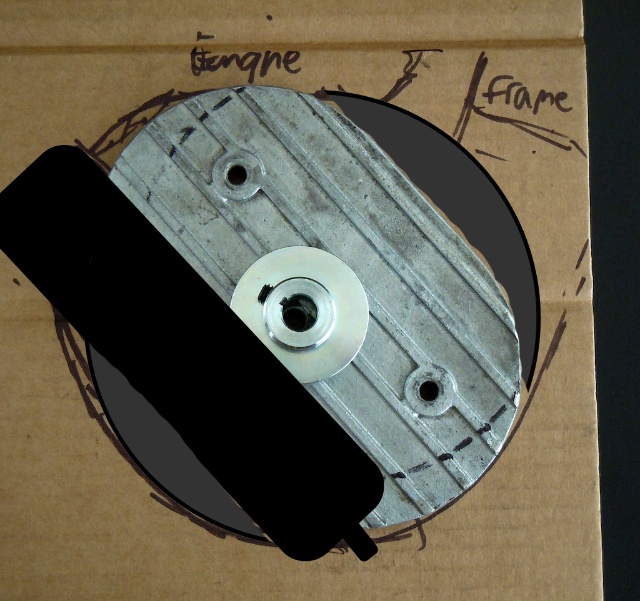

So today I went to Northern tool to find anything round with about a 6-3/4" diameter. I mostly struck out--I did find the smaller sheave wheel. But, my buddy Serg gave me a part off an old BMW that houses the air filter. It's quite "mechanical" looking; and I think if I combine it with something else, it might work. Here's what I'm talking about...

So you have to imagine something behind the these two pieces with the muffler in front. Maybe a larger Sheave wheel at the back...I dunno yet...I'm still looking for something. And you have to image the cast piece in the picture above painted black...basically it would look something like this...

or like this on the bike (with it painted black)...

And I guess on the back side it would look like this (in the mockup) if I did a sheave wheel...

Anyway...just thoughts. If you have any ideas, I'm listening...

By the way...did you see the toothbrush holder in the first two images? That guy is pretty darned ingenious!

And thanks for all of the kind words!

And this on the right...

Pretty darned clever if you ask me!

But I want to do something a little more representative of the period. Not sure what yet, but I'm thinking... So I took a piece of cardboard and traced out the opening. Here's the opening below the engine...

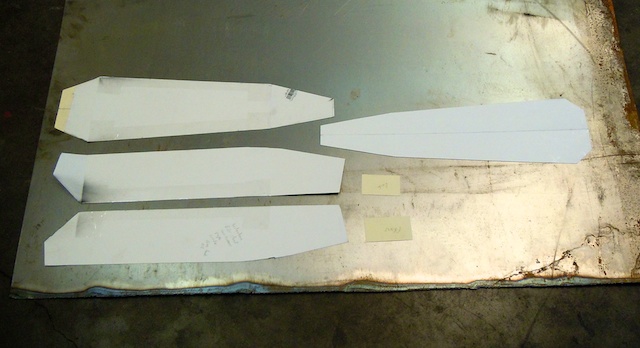

And here's my tracing...

So today I went to Northern tool to find anything round with about a 6-3/4" diameter. I mostly struck out--I did find the smaller sheave wheel. But, my buddy Serg gave me a part off an old BMW that houses the air filter. It's quite "mechanical" looking; and I think if I combine it with something else, it might work. Here's what I'm talking about...

So you have to imagine something behind the these two pieces with the muffler in front. Maybe a larger Sheave wheel at the back...I dunno yet...I'm still looking for something. And you have to image the cast piece in the picture above painted black...basically it would look something like this...

or like this on the bike (with it painted black)...

And I guess on the back side it would look like this (in the mockup) if I did a sheave wheel...

Anyway...just thoughts. If you have any ideas, I'm listening...

By the way...did you see the toothbrush holder in the first two images? That guy is pretty darned ingenious!

And thanks for all of the kind words!